Minerals Management Service

Minerals Management Service

- 73 pages

- May 5, 2008

EXECUTIVE SUMMARY

Oil and gas exploration and development is extending into deeper water in the Gulf of Mexico. The current record is 3,051 m (10,011 ft) in Chevron’s Toledo prospect in the Alaminos Canyon Block 951 in the Gulf of Mexico. This report was prepared to support the Minerals Management Service (MMS) regulatory decisions for oil and gas leasing. Given the recent development of subsea technologies, it is not surprising that very little information is readily available on the potential environmental effects. This report represents the compilation and synthesis of existing published and unpublished literature on the environmental effects of subsea operations on the deepwater environment. Technical experts from the oil and gas industry, regulatory agencies, and academic institutions were also consulted to identify potential environmental issues.

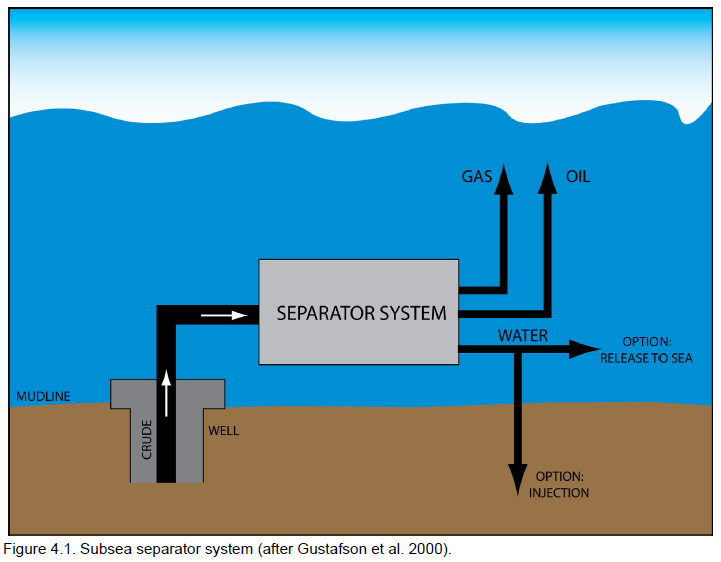

Four types of subsea processing technology are discussed in this report (Table ES.1).

Technologies that are currently being implemented in deep water include multiphase pumps

(Type 1) and partial separation with pumping (Type 2). Multiphase pumping systems are proven

technologies, whereas Type 2 systems have seen limited use. Technologies currently being

developed for future application include combinations of separators, scrubbers, and pumps that

allow complete separation of production stream at the seabed (Type 3). The most advanced

systems (Type 4) are likely to include multistage separation and fluid treatment with the

production of export quality oil and gas. The key environmental issue involved in the

implementation of these technologies is the handling and disposal of the produced waters and

sands. Options include transport to the surface, reinjection into depleted formations, or discharge

to the ambient environment.…

The Gulf of Mexico provides 95% of the United States’ total offshore petroleum production

(Gallaway et al. 2001). As demand for increased domestic oil supply increases, and new

technologies for accessing deep sea petroleum reserves are developed, oil and gas exploration

and production activities are expanding into the deeper portions of the Gulf. In addition to

fostering oil and gas production, it is the responsibility of the Mineral Management Service

(MMS) to protect environmental resources.The purpose of the study is to provide information to support the MMS regulatory decisions

for oil and gas leasing. This was accomplished through the compilation and evaluation of

information on the available technologies and potential environmental effects of subsea

processing activities. Potential technological impacts were evaluated relative to the sensitivities

of the deep sea environment in the Gulf of Mexico.Oil and gas exploration and development activities are extending into deeper and deeper

water in the Gulf of Mexico. The current record is 3,051 m (10,011 ft) in Chevron’s Toledo

prospect in the Alaminos Canyon Block 951 in the Gulf of Mexico. The costs of deepwater

exploration and development efforts are substantially greater than in shallower waters and

require equipment and facilities capable of withstanding the rigors of deepwater applications. In

addition, yields from wells in deep water are limited by the forces required to lift product from

the seafloor to processing facilities on the sea surface.Hazards from storms and oceanographic conditions are more significant for surface platforms

than for facilities located on the seafloor. In 2005, Hurricanes Katrina and Rita significantly

damaged or destroyed approximately l3% of the 4,000 oil and gas platforms regulated by MMS

in the Gulf of Mexico (USDOI, MMS 2005). Therefore, subsea processing affords opportunities

to maintain production under adverse conditions.Two main factors limit petroleum production in deep waters, pressure and temperature. The

pressures required to lift the product to the surface are substantially greater in deep water than in

shallow waters. At abandonment, typical wellhead pressures in shallow waters are on the order

of 0.69 to 1.4 MPa (100-200 psi); whereas deep sea wellhead pressures may be 6.9 to 13.8 MPa

(1,000-2,000 psi) (Devegowda and Scott 2003). Installation of long multiphase flowlines from

wells to surface processing platforms, while reducing costs, increase backpressure on the wells,

thereby reducing flow rates and recoveries (Devegowda and Scott 2003). The significant

differences in temperature between the seawater and petroleum product may cause partial

separation of the oil, gas, and water components (slugging) and the formation of hydrates1 and

waxes in the pipeline risers. Hydrate and wax formation may significantly impede flow in the

risers (Det Norske Veritas (USA), Inc. 2004).…